Sustainability and Yarwood Leather – The Key Points

Yarwood Leather is a by-product of the meat industry.

100% of our raw materials are UK sourced ox and heifer hides.

No deforestation occurs in our supply chain.

No harsh preservatives are used when transporting our raw material.

Chrome VI is not present in our leather.

Our tanners are a Leather Working Group Gold Rated tannery.

Our leather hides have a field to end-user traceability.

Leather is a long-lasting product which can easily be repaired, restored and reused.

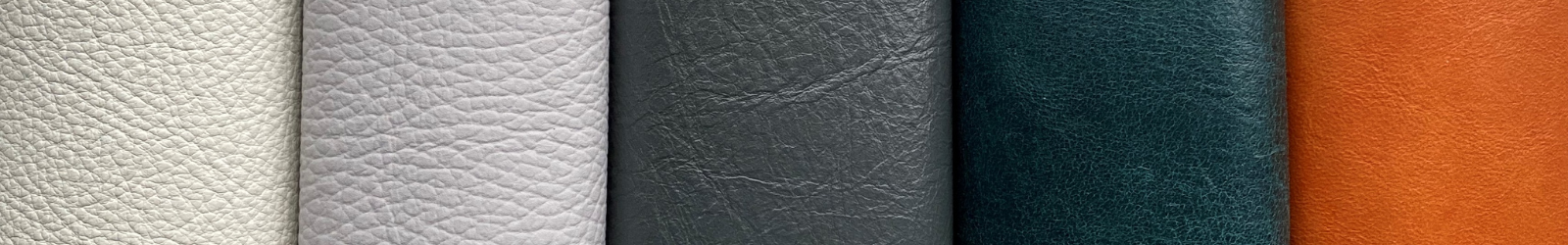

The Lifetime of Leather

Leather requires basic upkeep when it comes to caring and cleaning and is a material which wears in with use, adding character and charm on the seating through time. If looked after properly, leather is a material which creates individual furniture which can last a very long time.

Leather seating should not need to be replaced; it is more commonly replaced due to an aesthetic design change. Normal wear and tear issues through the seating’s lifetime can also be fixed relatively easily and without a lot of resources.

Leather can be recycled, repurposed and upcycled and is biodegradable.

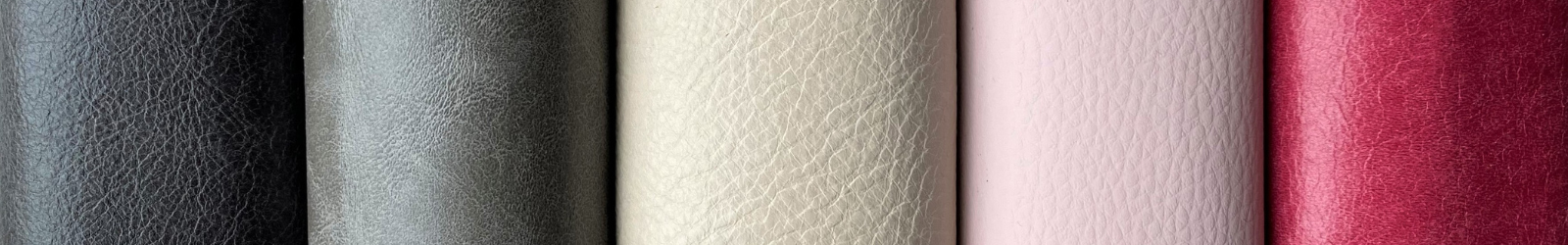

The Yarwood Leather Story

At Yarwood, we believe it’s important to understand where our products have come from and how they were produced.

Our leather is a by-product of meat production and is a natural way of recycling an otherwise wasted product. The value of a hide in comparison to the meat of an average cow is slightly less than 5%. By up-cycling bovine hides, the leather industry prevents millions of tons of waste. The process of creating a natural and long-lasting product such as leather adds value to what would otherwise be added to landfills or incinerated every year.

Yarwood Leather only use UK sourced ox and heifer hides to produce our leather. We have established relationships with our UK raw material suppliers, which enables us to trace our raw material back to its UK farm origin. Being UK sourced, we can ensure that no part of our leather supply chain is from areas where deforestation occurs for the use of grazing land.

UK quality hides are selected fresh and immediately refrigerated. They are then transported on refrigerated trucks to Italy, where the Italian craftmanship turns the raw material into a beautifully finished leather. No harsh preservatives of any kind are used when transporting our raw material.

Our production facilities and supply chain are carefully checked to ensure that the workforce is treated fairly and that all chemical products used comply with all European standards for health and safety. Our tanneries work to REACH and ISO14001 regulations, meaning they identify and manage the risks of using chemicals in the manufacturing process and also abide by government protocols to reduce, reuse and recycle water consumption. The tannery which carries out all our tanning is Leather Working Group Gold Rated.

Chemicals are used throughout the manufacturing process, in removing hair from the hides, in tanning the leather and in the finishing process. It is therefore essential to ensure that the chemicals used are of the highest quality, checks are in place to make sure that this is the case. The process itself dictates that only such chemicals are used, and therefore only quality suppliers are selected.

Processes are also in place to ensure that chemicals are not allowed back into the water supply and that contaminated water is disposed of correctly. Our tanneries work to REACH regulations, meaning they identify and manage the risks of using chemicals in the manufacturing process.

During the manufacturing process, water is put into the hides to wash them in the first instance. It is also used when adding chemicals to the hides, to help them bind, and then to wash away any remaining chemicals. Finally, water is removed from the leather in the drying processes. A tight process is in place at the tannery to ensure that water is reprocessed correctly before being released back into natural water sources such as rivers. The local government in Italy where our tannery is based has strict rules and controls on water usage. Separate drains are used to ensure that any contaminated water does not flow back into natural water sources but is licensed and metered and sent to a dedicated depuration plant under local government control.

Both of these operations are checked by second and third-party audits, to ensure that there is as little environmental impact as possible.

The Leather Industry as a whole is continually improving to make processes even more sustainable and environmentally friendlier.

We carry out regular visits and audits of our suppliers to ensure conformance, in this way we can ensure ethical fair treatment as well as product quality all the way from field to end-user.

Yarwood Leather

As a company, we are continually researching and assessing new ways to further improve the sustainability of leather.

Our team and supply chain as well as others in the industry are researching new technologies to help the sustainability of leather. Our supply chain is made up of companies which are people driven and who want to further progress this historic industry.

As always, our team are more than happy to help with any questions you may have, please get in touch.